Right next to the Hornet Museum, on western Alameda Island, sits the new $50 million Ron Cowan ferry maintenance facility, opened at the end of last year. Inside, workers toil away fueling and maintaining the ferries that carry commuters around the Bay.

From the website of Water Emergency Transportation Authority (WETA), which operates many of the Bay Area's ferry services:

The Ron Cowan Central Bay Operations and Maintenance Facility is the new home of the San Francisco Bay Ferry fleet in the central bay, providing a consolidated base to maintain vessels operating on its Alameda/Oakland, Alameda Harbor Bay, Richmond and South San Francisco ferry routes. The facility also includes an Operations Control Center for service dispatch and an Emergency Operations Center that will serve as a primary location for WETA to coordinate the provision of emergency transportation services in the event of a regional disaster or transportation disruption.

Streetsblog got a look inside this facility on a recent Friday morning, to see exactly how WETA's people keep the ferries sailing and afloat, and how the building better helps them prepare for potential emergencies.

Frank Hernandez first learned engine and transportation maintenance in the Air Force, and then took a maritime job in Seattle, before becoming Engineering Manager for WETA's Blue and Gold Fleets. "Before this facility, our infrastructure was scarce," he explained. In fact, WETA didn't even have enough dock space to bring in all of its fleet at once for fueling and maintenance, which often meant driving crews between South City and Pier 41 to take care of the boats. Sometimes ferries were even forced to bob off shore waiting for a place to come in. "Now we have all our crews and engineers in one spot."

The new facility can handle twelve boats.

They also now have a 42,000 gallon fuel yard, which can keep the fleet running for a week, carrying first responders in the event of an emergency. The fuel tanks are automatically measured and anyone at the facility can keep tabs on fuel capacity by looking at a phone app. "Prior to that, we had to open the tank and measure the level with a ruler," said Hernandez. When the boats come in after the morning or evening runs, crews can watch the flow of fuel around the facility and into the boat's tanks from their phones. They also top off the boats' urea tanks--a chemical added to engine exhaust to eliminate smog-producing emissions. "And we add lube oil and offload dirty lube oil."

The facility is also equipped to handle R-99--a mix of bio diesel and conventional fuel.

The facility also allows WETA to repair all but the most major damage onsite.

They have spare props on hand, for example, which can be replaced by divers. "A prop can be changed out in five or six hours," said Hernandez. There is also a sophisticated welding facility to repair steel, copper, aluminum, or alloy pipes and parts. WETA employees are trained here on welding techniques, which Hernandez says are as much "art as science." Previously, repairs had to be contracted out, and could take weeks.

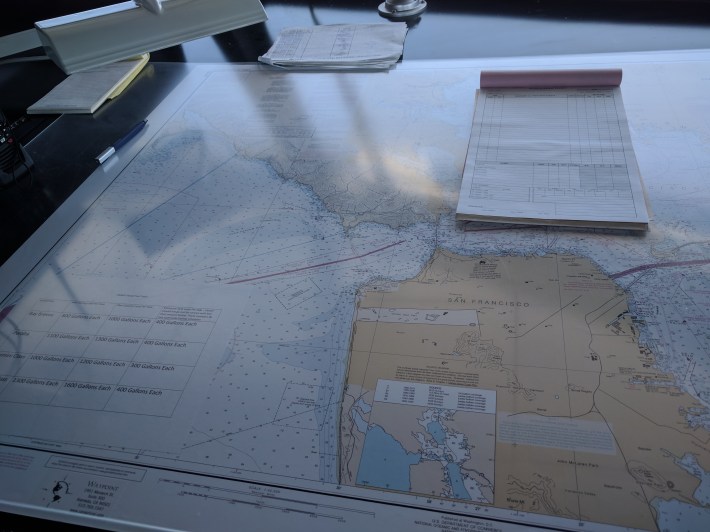

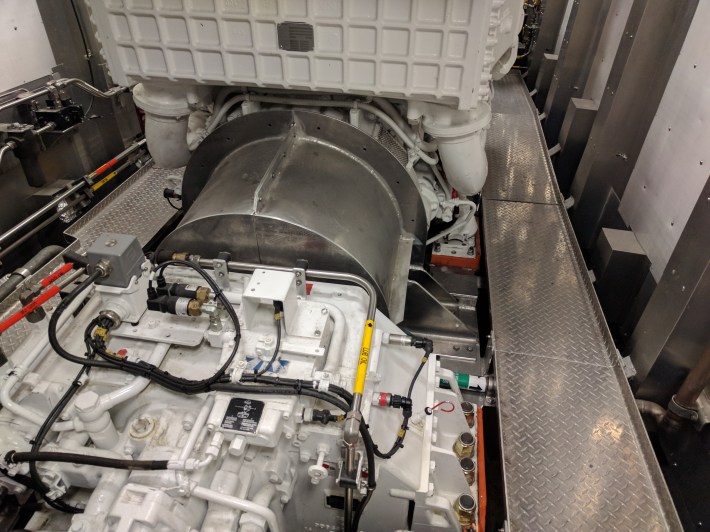

WETA also showed Streetsblog one of the newer boat's engine rooms--and the redundancy that assures that even the most severely damaged boat could still limp home. Each boat has two independent propulsion systems, each equipped with its own electrical generator and backup batteries. Each engine has twelve cylinders and generates 1800 horsepower.

From the pilot house, ferry operators can look into the engine rooms via video cameras, and remotely trigger fire suppression systems if needed. Crews regularly drill for such emergencies, working with the Coast Guard to simulate fires and test crew reactions.

Meanwhile, each large ferry carries the equivalent of nine busloads of passengers, or about 445 people. Smaller boats carry around 200 people. To improve efficiency, WETA is looking at reducing weight, incorporating more aluminum parts and lighter seating materials. They also are looking at fuel cells and hydrogen for future propulsion systems, but, for now, diesel is still the best fuel in terms of energy per pound of weight.

Of course, they also carry bikes. Hernandez pointed out one project their shop is working on that he thought would be especially interesting to Streetsblog readers. They ordered a bunch of bike hooks online and found that, over time, the rubber sleeves on them tend to wear out. WETA workers have figured out a vinyl dip coating that seems to wear better. He said he'd like to hear from ferry riders what they think of the new coating, so please post your comments below.

The tour was a reminder of everything that's involved in keeping the machinery of the Bay Area in safe, working order. So keep that in mind next time you take a ferry--they don't run without sweat, skill, patience, and a whole lot of spare parts at facilities such as this one.

More pics of the facility and the guts of the ferries below: