Note: GJEL Accident Attorneys regularly sponsors coverage on Streetsblog San Francisco and Streetsblog California. Unless noted in the story, GJEL Accident Attorneys is not consulted for the content or editorial direction of the sponsored content.

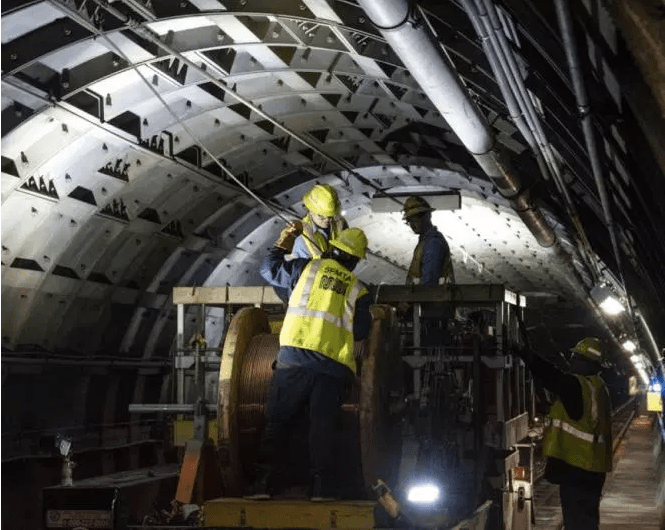

Muni rail will be closed for the rest of the year. That was a takeaway from Tuesday's SFMTA board meeting and a presentation from Muni's Director of Transit, Julie Kirschbaum, and Charles Drane, Acting Deputy Director of Maintenance of Way. The reason: the overhead wires that power Muni's trains and trolley buses contain 154 splices of the same model pictured below, built by Phoenix Mining and Transit Systems of Cincinnati, Ohio. And in the three days the Muni rail system was open last week, two of them failed.

That means the entire system would be in jeopardy of passing trains tearing down wire, potentially leaving passengers stranded in the tunnels. "Having two instances in 72 hours further contributed to our decision to close down the rail system," Kirschbaum told the Board. "The splices are customized to our specifications and require highly specialized manufacturing."

Metallurgical tests are still pending on the splices that broke last week, but a splice failure from Muni's April 2019 meltdown (the one that lead to the ouster of former Director Ed Reiskin) was analyzed.

Drane said the splice pieces failed "tensile and pressure" testing. He added that after the 2019 failure additional splices were tested, some straight out of their delivery boxes, and some showed additional metallurgical weaknesses. "We have some uncertainty about the quality of the splices we're receiving from Phoenix Mining."

But some questioned why Muni was using this splice type in the subway to begin with. Or why they continued to install them after last year's failure and findings. Or why Muni, knowing there was a potential problem, didn't do a "dress rehearsal," running a full schedule but without customers, before opening to the public. "We did do some testing but we should have done more," said Kirschbaum. They also said the handful of initial failures weren't originally thought to indicate a system-wide problem.

The Muni splice design, which engineers refer to as a "battleship" because of its shape, allows electric trolley buses and light rail to draw power from the same wires--something that's essential on streets where wire is shared by trolley buses, historic trolleys, and light rail. But buses and historic trolleys don't use the subway tunnels.

"The splice type is a design that we have mostly phased out in the U.K. on mainline and light rail," explained Ryan Scott, a specialist in overhead wire systems with the American consulting arm of the U.K.'s Network Rail, in an email to Streetsblog. "The newer ones are easier to install, generally lighter and more reliable."

Muni officials said they are now purchasing the newer type of splice (pictured above) to replace the battleships in the subway.

Meanwhile, Scott isn't convinced by the photo alone that the failure is the sole result of a manufacturing problem. "The fracture being at the bolt location could be indicative of either material failure, installation issue or a combination of the two. Over tightening the bolt, the geometry of and tension in the contact wire and uplift force from pantographs resulting in excessive force on the splice could each alone or collectively lead to such a failure." he said. "To get to the root cause and fully understand the issue and identify the required corrective actions going forward I would look at all aspects, the lab results on the splice failure, the work records for the splice installation (including the torque settings for each of the bolts), the tension in the wire at that location, the heights and staggers of the wire at the adjacent supports and the uplift force of the pantograph at time of failure. Only then could fuller conclusions be drawn."

Streetsblog has requested that data from SFMTA and will update this post (or include the information in a followup). Streetsblog also reached out to an engineer at Phoenix Mining. The engineer did not immediately respond.

At yesterday's meeting, Director Steve Hemminger asked if Muni tests essential parts before installation. "We depend on our manufacturers to deliver as specified," Drane replied. However, the Muni officials promised to start proactively doing "sophisticated testing."

Hemminger also wanted to know if having 154 splices in the subway was too many. "I can't speak to whether or not we're over splicing," said Kirschbaum. "We are going to be reaching out both nationally and internationally to make sure Charles has a peer in Lyon or in Seattle that he can call up," she said. "We have a tremendous talent pool at this agency but we are often relying on knowledge handed down from generation to generation of maintenance staff and we want to learn as much as we can from other systems so that we can answer the same question you just posed."